|

How to Select the Right Bearing?When selecting from among these many varied types of bearings, the bearing that is right for your machine, the following two criteria are very important.

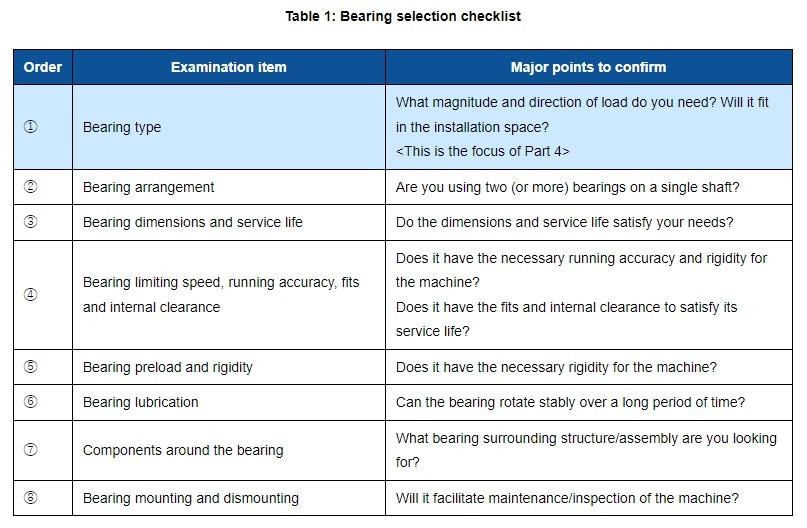

The order of priority for selecting bearings Please note that the following order is only a guideline.When you actually select the bearing to use, the most important factors are past success history and points of improvement, so it is not necessary to follow this order to the letter.

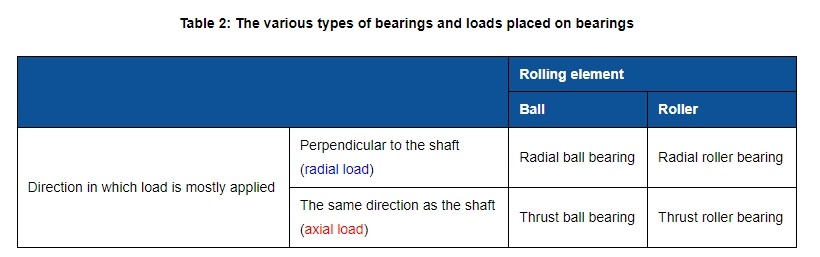

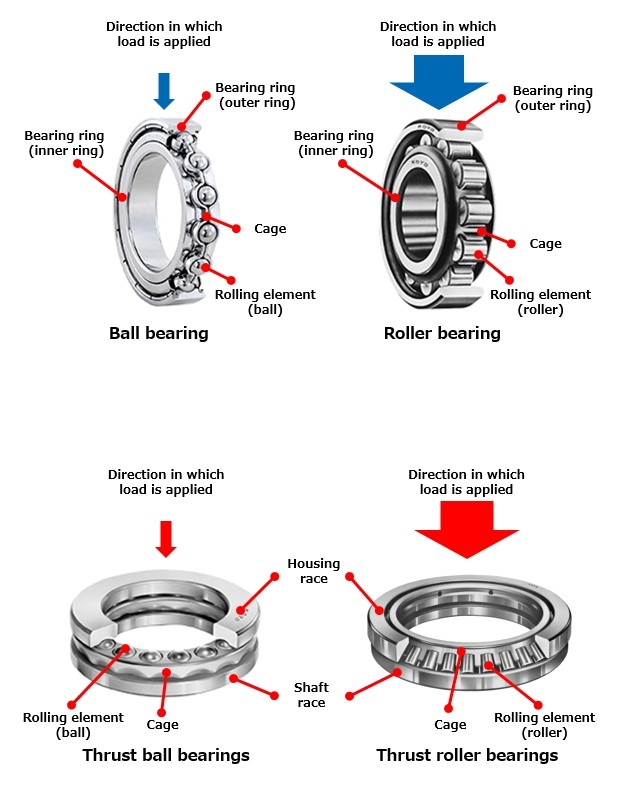

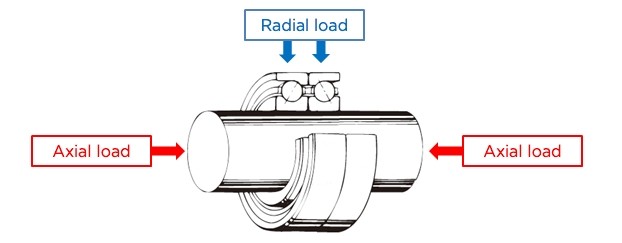

① How to select the type of bearingWhen designing a machine, most people first decide on the dimensions of the shaft to satisfy the strength requirement, and then select the bearing based on that. 1) If the load will be mostly radial (perpendicular to the shaft), use a radial bearing, and if the load will be mostly axial* (same direction as the shaft), use a thrust bearing. * Axial loads are sometimes called thrust loads. 2) If the load on the bearing will be light, use a ball bearing, and if it will be heavy, use a roller bearing.

3) If a radial load and an axial load are both placed on a single bearing at the same time (combined load), a light combined load calls for a deep groove ball bearing or an angular contact ball bearing, while a heavy combined load calls for a tapered roller bearing. 4) If there is a heavy axial load being applied from both directions, you can combine two or more bearings, or use a double-row bearing.

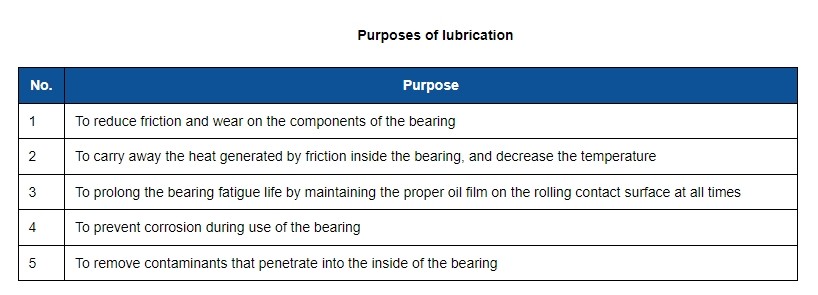

Bearing installation spaceSelect a bearing type that will fit in the installation space based on the dimensions of the shaft or housing. ② Bearing arrangement Arrangement means what kind of bearings, and how many of them, to put in place relative to the shaft. In a standard machine, normally combining two (or more) bearings on a single shaft will provide additional load. here are two key points to decide on the arrangement of bearings.Thermal expansion should be considered In consideration of the applied load conditions, the fixed side and the free side should be separated. A free side bearing to prevent expansion and contraction of the shaft due to thermal expansion.③ Limiting speed Once the bearing reaches a rotational speed equal to or greater than a certain amount, its temperature will increase tremendously, impairing the ability of the machine to run smoothly. This certain amount is called the "limiting speed." You should select a bearing with a limiting speed that is higher than the rotational speed in accordance with the operating speed of the machine. Select the best bearing "fit" based on the load direction and conditions. Select the bearing internal clearance based on the operating clearance. ④Bearing lubrication The primary purpose of lubrication is to reduce friction and wear. In order to prevent this friction and wear, oil or some other substance is applied between the contact regions. This is called "lubrication." With the appropriate lubrication, an oil film makes it so that the rolling elements and bearing rings do not come in direct contact. This results in less friction and a massive decrease in wear.

|