|

Bearing Mounting and Dismounting1. Precautions regarding the handling of bearingsBearings are high-precision machine components. They therefore need to be handled with care.

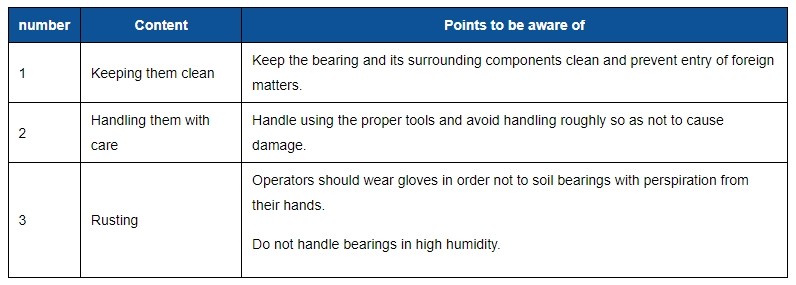

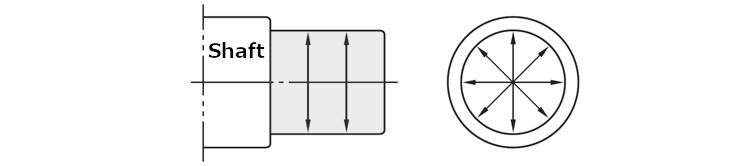

2. Bearing mounting1) Recommended preparation prior to mountinga)Preparation of bearingsJust before mounting, remove the bearings from their packaging. Since the anti-corrosion oil covering bearings is a highly capable lubricant, the oil should not be cleaned off if the bearings are used for normal operation. b) Preparation of shafts and housingsPerform cleaning and check whether there are flaws or burrs as a result of machining. Be particularly careful to completely remove things like casting sands and chips from inside the housing. c) Inspection of shafts and housingsCheck that the dimensions, forms, and finishes of the shaft and the housing are accurate to those specified in the design.The shaft diameter and housing bore diameter should be measured at the several points as shown in Figures 1 and 2.

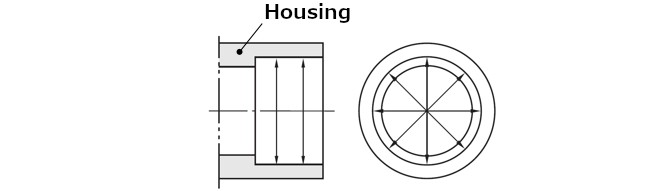

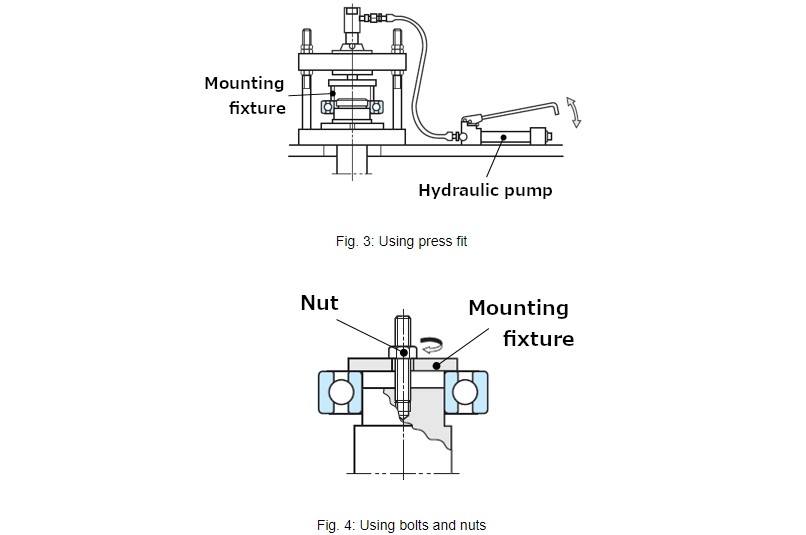

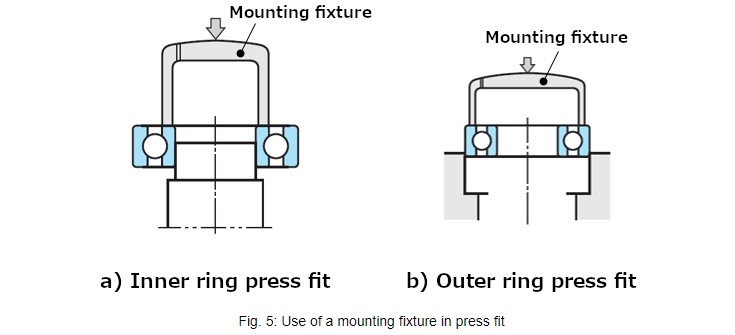

Just before mounting the bearing, machine oil should be applied to the fitting surfaces of the shaft and housing that have passed inspection. The mounting procedure depends on the type and fitting conditions of the bearing. Here we will explain about mounting a bearing by interference fit. a) Press fitWhen mounting small size bearings with restricted interference, press fit is applied. The most widely used methods of press fit are by use of a press (see Figure 3) and use of bolts and nuts (see Figure 4).

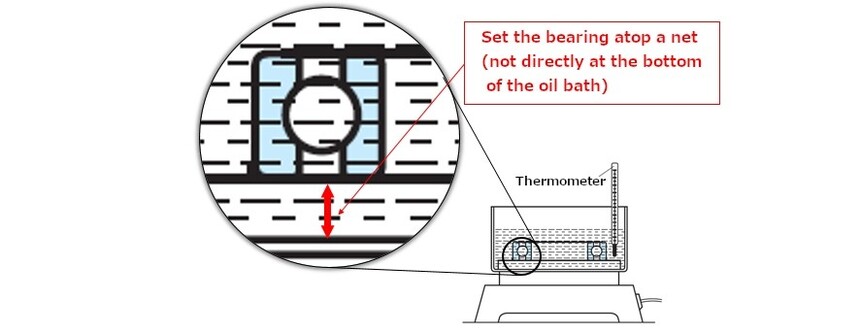

Both of these press fit methods involve using a mounting fixture to apply force evenly to the bearing to mount it slowly with care (see Figure 5). b) Shrink fit (interference fit of inner rings)When mounting bearings that allow heavy interference onto a shaft or large size bearings, shrink fit is applied.Shrink fit, which expands bearings by heating them, has the advantages of not applying too much force to bearings and taking only a short time.The most typical method of shrink fit involves heating the bearing in an oil bath (see Figure 7).

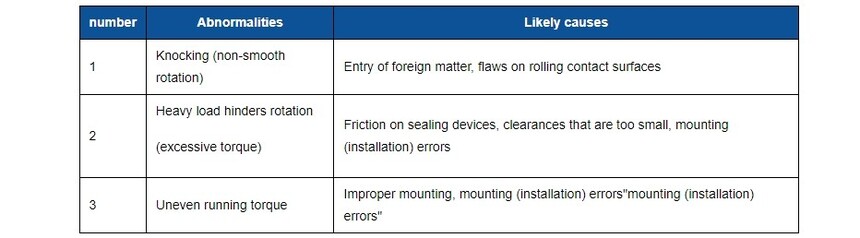

c) Cooling fit (interference fit of outer rings)This method fits bearings into housings by cooling them with dry ice or equivalent.Since moisture in the atmosphere adheres to bearings, proper rust preventive treatment is required. 3)Checking the bearing after mountingIf preload is required, apply preload to the bearing and install a sealing device. a) Confirmation after mounting (before test run)With compact machines, rotation is checked by manual operation, in order to ensure that there are no abnormalities as indicated in Table

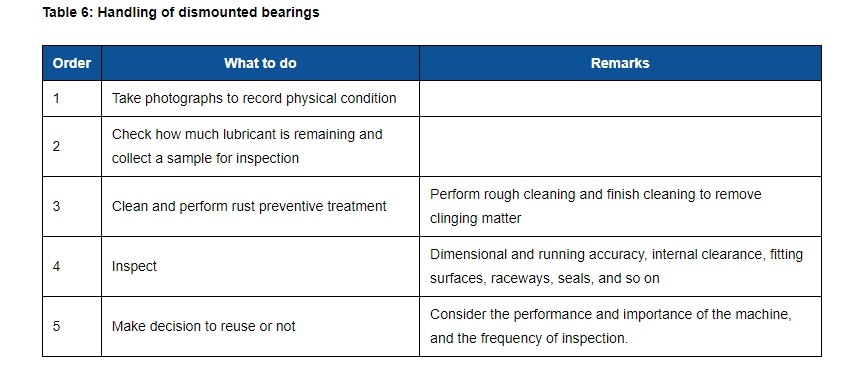

For large machines where manual operation is not possible, idle rotation of the bearing is performed under no load by turning off the power source immediately after turning it on. This allows us to check that there is no abnormal vibration or noise. b) Confirmation during test runWhen performing the test run with a driving force, start under no load and at low speed, before gradually increasing to the specified conditions.Check the noise, increase in temperature and vibration, and, if any abnormalities occur, perform inspection promptly.Bearings may be dismounted as necessary in order to perform the inspection. 3. Bearing dismountingWhen dismounting a bearing for reuse or to find the causes of damage, just as when mounting, it is important to take care not to damage the bearing or the surrounding components.Since bearings mounted by interference fit are especially easily damaged during dismounting, it is particularly important to take care not to damage them. 1) Inner ring dismounting methodsSome typical methods of dismounting the inner ring are the method that uses a press and the method that uses special tools. a) Dismounting by use of a pressIf it is possible to perform dismounting by use of a press, this is the simplest method.Force is applied to the inner ring using the dismounting fixture. When dismounting the inner ring, make sure that the dismounting fixture does not come in contact with the outer ring.If the dismounting fixture comes in contact with the outer ring, damage will be caused to the bearing's raceway surface. b) Dismounting by use of special toolsWhen dismounting with special tools, the jaws of the tool should firmly hold the side of the inner ring. 2) Outer ring dismounting methodsTo perform dismounting of an outer ring with interference fit, notches or bolt holes should be provided on the housing shoulder. 4. Maintenance and inspection of bearingsEarly detection of failures and prevention of sudden damage to the machine, through periodic and proper maintenance and inspection of the bearings, are very important for the enhancement of productivity and profitability.

|